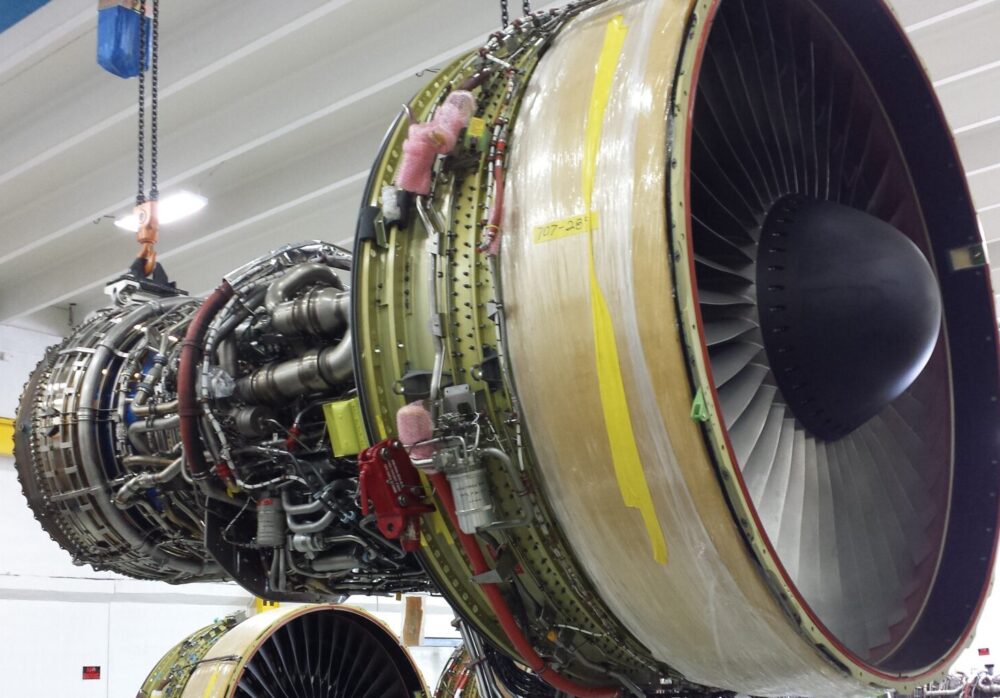

Vortex Aviation specializes in aircraft turbine and other aviation equipment repairs. They needed a fast system that would help them suspend and maintain expensive equipment while their mechanics work on them. Their main pain points were risk of potential damage of their clients’ equipment and the safety risk their staff members are exposed to on a busy maintenance floor.

Vortex required an efficient, turnkey system with automated safety warnings.

MHS engineers designed and customized two 10T overhead cranes with four 5T electric chain hoists and two 2T electric chain hoists to fit the Vortex’s need for an efficient system. The trolleys, bridge and hoists were adapted to have variable speed for greater control and adaptability to incoming work volume. In addition to an already efficient system, we provided motion-activated strobe lights and optical collision sensors for increased safety on a busy floor.

Our turnkey installation ensured our customer would be able to get to work as soon as the installation was finalized, while our expert trainers provided on-site operator training based on OSHA standards.

We provided a system that not only addressed Vortex Aviation’s pain points, but also optimized their workflows.